The separators

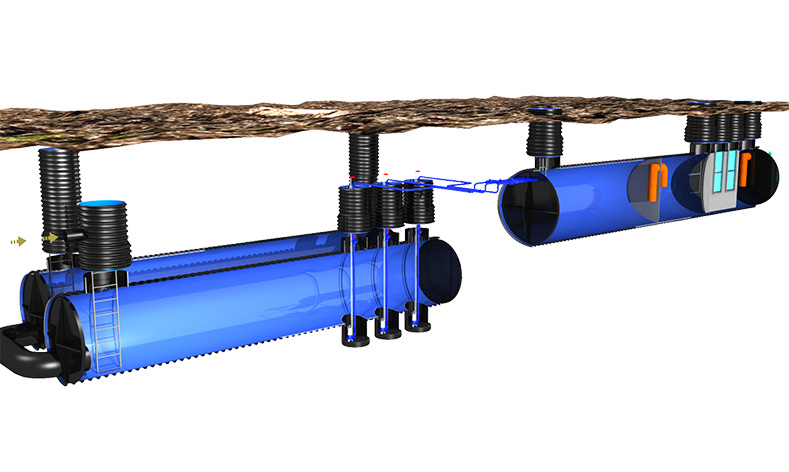

The separators are manufactured using PALADEX® pipes, employing a unique technology that combines polyethylene and galvanized steel.

The separators are custom-designed to meet the specific needs of the clients. Depending on their use, they can be installed above ground (thanks to their UV protection) or buried. Their high ring stiffness and reduced weight allow them to support significant loads from the ground, without requiring concrete protection.

The separators are produced in a wide range of volumes and are suited for various applications.

There are several types of separators:

- Grease and fuel separators

- Sludge and collected waste separators

- containment chamber

Grease and fuel Separators:

Paladex based oil and fuel separators, a pipe manufactured with a unique technology which combines polyethylene and galvanized steel.

Grease separators are made from PALADEX® pipes, using a unique technology that combines polyethylene and galvanized steel.

The separators have high ring stiffness and a lightweight design, enabling them to withstand high ground loads without the need for protection by a concrete layer.

They are manufactured in an unlimited wide range of volumes, and for various applications.

Grease separators are specifically designed to separate oils and fuels using filters prior to flowing them into the drainage system.

They are available for both underground and above-ground installation, with capacities ranging from 80 to 300 liters per second.

Compliant with EN1825 standards and the European Standard 858, these separators are available in both vertical and horizontal configurations

They are capable of withstanding groundwater pressures of up to 7 meters maximum.

Separators are customized according to the designer’s specifications and site conditions, allowing them to be manufactured in any configuration to meet the specific requirements.

The separator is equipped with an automatic sealing system, which can be remotely controlled via a mobile application.

Technical information

Sludge and collected waste separators:

The waste collected and sludge separators made from PALADEX® pipes, combining polyethylene and galvanized steel, thanks to an exclusive technology.

With their annular rigidity and low weight, the separators can withstand high loads without requiring additional protection, such as a concrete coating.

The systems, designed for surface or underground installation, offer storage capacities ranging from 5,000 to 50,000 Liters and are manufactured in a wide range of volumes, depending on the specific site requirements and the designer’s recommendations.

They can be configured with multiple compartments or double compartments.

Sludge and waste collected are removed by pumping or mechanical collection.

Their primary separation function (of liquids and waste) reduces damage to treatment systems and prevents pump shutdowns.

They also prevent the passage of heavy and floating solids into sanitary and industrial sewage systems.

A sludge separator is a used to purify water or other fluids by removing solid impurities before they are treated or discharged. they are commonly used in wastewater treatment plants, stormwater management systems, as well as in industrial facilities where it is necessary to separate heavy solids from fluids to prevent equipment clogging or contamination of drainage systems.

In summary, the sludge separator primarily serves to:

- Separate solid particles (such as sand or sludge) from liquids.

- Protect equipment by preventing clogging from solids.

- Improve the quality of water or effluents before treatment or discharge.

Confined Chamber

Confined Chambers are made from PALADEX® pipes using a unique technology that combines polyethylene and galvanized steel.

They offer have a high ring stiffness and a low weight, allowing them to support significant ground loads.

Each system integrates a double tank (one inside the other), forming a unified structure that serves both as a storage tank and a spill containment tank.

The volume of the outer tank exceeds that of the inner tank by more than 20%.

Examples of use:

- Protecting sewage pipelines passing over Mekorot boreholes.

- Storage of hazardous materials.

- Oil storage

- Maintaining a high-water temperature during winter

Advantages:

- Unlimited storage capacity available.

• Resistant to a wide range of chemicals due to the polyethylene.

• Available in horizontal and vertical configurations.

• Lightweight and easy to transport.

• Galvanized steel structure coated with polyethylene, eliminating the need for cathodic protection for underground installations.

• Equipped with inspection and drainage chambers for both storage zones.