Spiral Pipe

PALADEX® is a large diameter spiral-wound pipe made from high-density polyethylene (HDPE) reinforced with steel.

The technology was originally developed in Japan in the 1980’s.

The PALADEX® technology is achieved by combining polyethylene and galvanized steel with an omega, profile while using a unique pasting process of the layers.

The pipe consists of a smooth inner layer of polyethylene, a corrugated outer layer of polyethylene and galvanized steel sandwiched between the two.

The galvanized steel is further protected by two layers of polyethylene, ensuring uniformity and perfect adhesion between the materials.

The pipe’s spiral structure is characterized by extraordinary strength and low weight.

The combination of high-strength steel and polyethylene, with optimal hydraulic properties and strong chemical resistance, gives the pipe high mechanical strength and a reduced weight, these advantages are fully utilized in PALADEX® pipes, designed for gravity-fed liquid transport and various types of storage tanks.

PALADEX® is specifically designed for underground, non-pressure drainage systems and wastewater applications.

Technical information

High ring stiffness

Easy and quick installation

Low weight compared to concrete (1:30 ratio)

Polyethylene resistance to wide range of materials

Resistance to internal pressure of 0.75 bar

Manning roughness coefficient of 0.009, allowing design with a small slope

High wear resistance

High ring flexibility

Corrugated Pipe

A Corrugated pipe with an outer structured wall and a smooth inner made of polyethylene.

Polyethylene, a thermoplastic polymer, offers many advantages such as a high modulus of elasticity that provides the pipe a high ring stiffness while remaining lightweight, outstanding resistance to extreme temperature and chemical agents. It is used in various industries and has recently gained importance in the field of fluid conduction.

The pipe is designed with annular sections, allowing it to be shortened at any point, which simplifies on-site installation and connection to manholes. Its low weight also improves installation performance.

Pipes are manufactured, tested and approved in compliance with the international standard of ISO21128 based on the inner diameter.

The Paladex pipeline is manufactured with SN8-SN12 ring stiffness.

Connections and sealing

The connection of the pipes is made by fitting them together with a rubber gasket placed between the first two corrugations of the pipe.

The connection can withstand an atmospheric pressure of 0.5 bar according to standard.

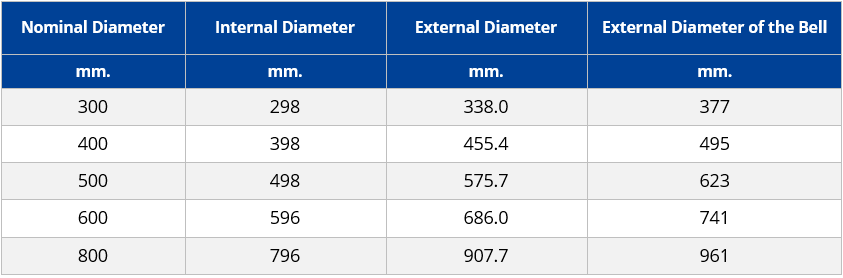

Dimensions: Pipe in a standard length of 6 meters.