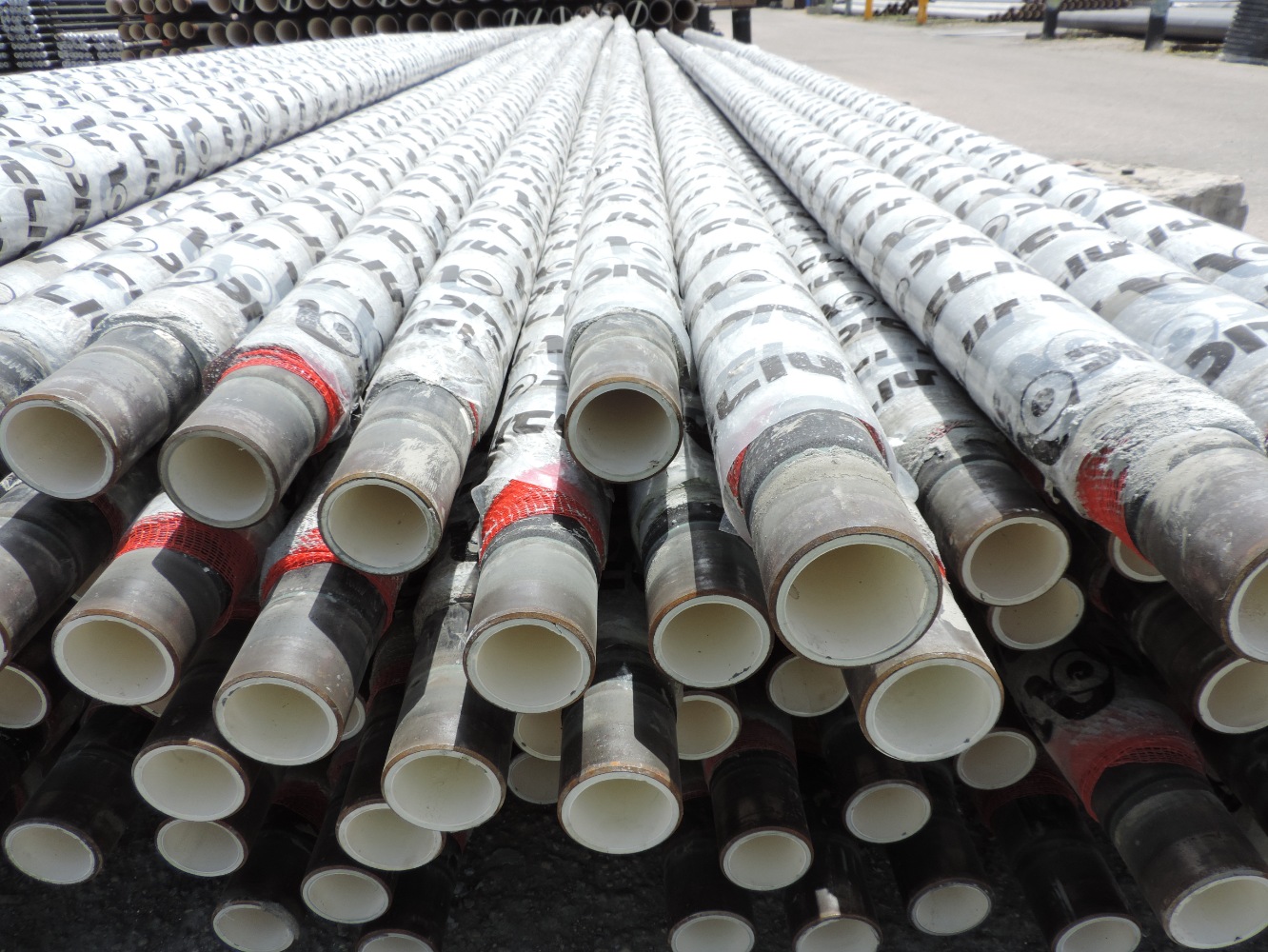

Compressed concrete coating – APC4

Compressed concrete coating in compliance with Chemical Industry requirement 266.4 excels in the excellent mechanical protection of the pipe. This coating is built from a mixture of concrete reinforced with a polymer mesh and special plastic fibers to prevent cracks. The stiffness and strength of the coating allow for the laying of pipelines without the need for lining the channel. The coating is especially suitable for mountainous and rocky terrain.

Technical information

Compressed concrete wrapping and APC4 – Technical specifications

These specifications describe the technical requirements and properties of a compressed concrete wrapping on steel pipes. Generally, these pipes are coated with internal cement as protection from corrosion. The designation of compressed concrete wrapping is: Anti-corrosion and mechanical protection. Pipes that are wrapped in compressed concrete can be placed directly in the channel without the need for a sand bed. The pipes are suitable for direct placement on rocky soil.

Sorting and naming

20mm compressed

Compressed concrete 20mm thick applied directly on top of the external pipe casing.

APC-4 compressed concrete 20mm thick applied to a plastic wrapped in extruded polyethylene (APC-3) which constitutes an anti-corrosive protection.

Pipes and Materials

The pipes and materials used to make the coating will conform to the standards and specifications which apply to them, as specified below:

Pipes

The pipes will conform to the requirements of Israeli Standard 530 or 10255. The inner coating will conform to the Chemical Industry requirement 266.1.

Materials

Material including cement, gravels, reinforcement mesh and additional materials will conform to the Chemical Industry requirement 266.4.

Coating Layer

The coating layer is made of one piece and consists of cement and mineral gravel which reinforce the concrete and reduce water absorption, a polymer mesh which supports the cement, polymer fibers which strengthen the concrete and reduce the concrete’s tendency to crack and other additives which enhance the durability of the concrete.

The compressed concrete is wrapped with a plastic sheet used for finishing, marking the concrete and to prevent the loss of water during curing. (Note: after the concrete hardens it is possible to remove the sheet from the pipe). The end of the pipe is not wrapped and allows welding and connecting the pipes in any acceptable manner.